Industrial Safe Havens

- SF: 86,600

- NC, KY, and IN

- Safe Haven Weatherization and Testing

Safe havens are designed to protect people from chemical, biological, radiological, and explosive threats.

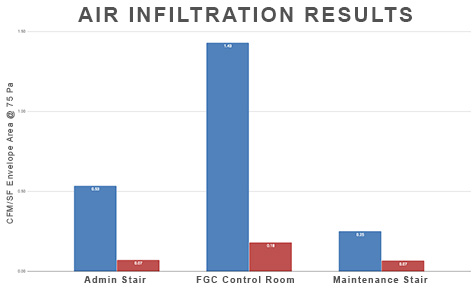

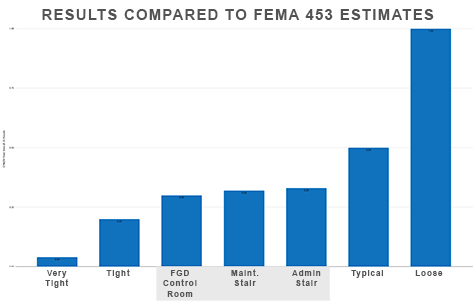

We assessed the air infiltration rates in the intended locations for the safe havens. We also provided a scope of work for reducing this leakage and installing HVAC upgrades to isolate the safe havens in according to FEMA Safe Room Guidelines.

FEMA Air Leakage Guidance Compared to Commercial Building Air Leakage Standards

Typical air-sealing measures included creating an airtight drywall system for the interior wall surface, using blower doors to assist with locating and sealing air leaks, installing a cleanroom ceiling system with cleanroom lighting fixtures, and installing HVAC controls and dampers.

For some of the safe havens, the interior finish (such as cabinets) restricted access and interfered with sealing air leaks. In those cases, the AeroBarrier™ sealing system was also used.

Testing after the sealing demonstrated an average reduction of 70% in the air infiltration rate. Reducing the air infiltration as much as possible reduced the size of the system needed to pressurize the space in the event of an accidental release of anhydrous ammonia.

Measured air leakage rates for the Safe Haven spaces.